🔗Automatic Ordering Part 3: Linking Parent and Child Items

Parent/Child links tell the system how cartons and packs relate — so that stock levels, sales, and orders stay in sync.

This isn’t just for automatic ordering. Once a child item is linked to a parent, all ordering and stock level control is handled by the parent, whether orders are automatic or manual.

Example – Carton and Pack:

-

Parent = Carton of cigarettes

-

Child = Single pack of cigarettes

When a pack (child) is sold or scanned in, the system updates the carton (parent) instead. This keeps your stock accurate across different selling and ordering units.

How to set it up

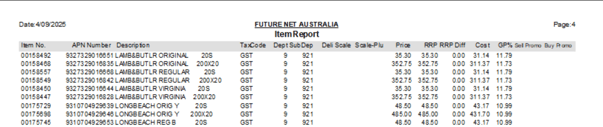

- Go to Printing → Item Detail Reports

- Select the department (e.g. Tobacco & Cigs) and preview the report

- Identify your Parent items (usually bulk/cartons) and their Child items (units/packs)

In this example, Item 00158492 is the child and Item 00158468 is the parent, usually shown with a size like 200x20.

- Go to Inventory → Items

- For each Child item, enter the Parent’s item number in the Parent Item field

⚠️ SPAR stores:

In SPAR systems, the pack is the Parent not the carton. Make sure you reverse the setup.

Why it matters

-

You’ll only need to order and receive the parent item

-

All stock movements (including sales of child items) are tracked through the parent

-

It avoids duplication and confusion in stock levels

Once linked, the child item’s stock level is no longer independent. The system will ignore it — all calculations will run off the parent.

✅ Once your items are linked

You're ready to tell the system how much stock to maintain. Let’s set your Min and Max levels.

👉 📦 Automatic Ordering Part 4: Setting Minimum and Maximum Stock Levels